Also, the fluctuations in the commodities prices are likely to influence the cost per unit as well. CPU is not just a financial metric; it’s your guide to attaining efficiency, creating informed pricing strategies, and achieving sustainable growth. Optimizing your Cost Per Unit is key to protecting your profit margins and positioning your business strategically in the marketplace. Value is what you get.” This quote holds true in the context of cost-per-unit analysis and reiterates the importance of a fine balance between production costs and market value. Businesses with complex cost structures and multiple factors influencing costs use this approach of activity-based costing (ABC). It links the costs directly to the activities or operations that drive them and helps evaluate resource consumption.

Ignoring external factors

When the company is aware of its cost of production, it can decide its pricing accordingly by keeping a reasonable margin for profit. Thus, it gives the company a fair idea of making decisions concerning price and analyzing its current cost structure. If the product’s cost is higher than the usual, then the company shall analyze the root cause for the same and take corrective action. Cost per unit equation is a crucial metric in evaluating financial performance.

Total variable cost

It costs Greg’s biggest competitor $8 on average to create a similar candle. For maximum insights, cost per unit should be tracked regularly – monthly, quarterly or annually. The fluctuations in cost per unit are obvious to occur, and the following factors contribute to it on a larger scale. Cost per unit is sometimes referred to as “Unit Cost” or “Unit Cost of Production”. It is the amount of money spent in producing one unit of a product or service. This cost per unit indicates that any car sold above $1200 will be a profitable deal.

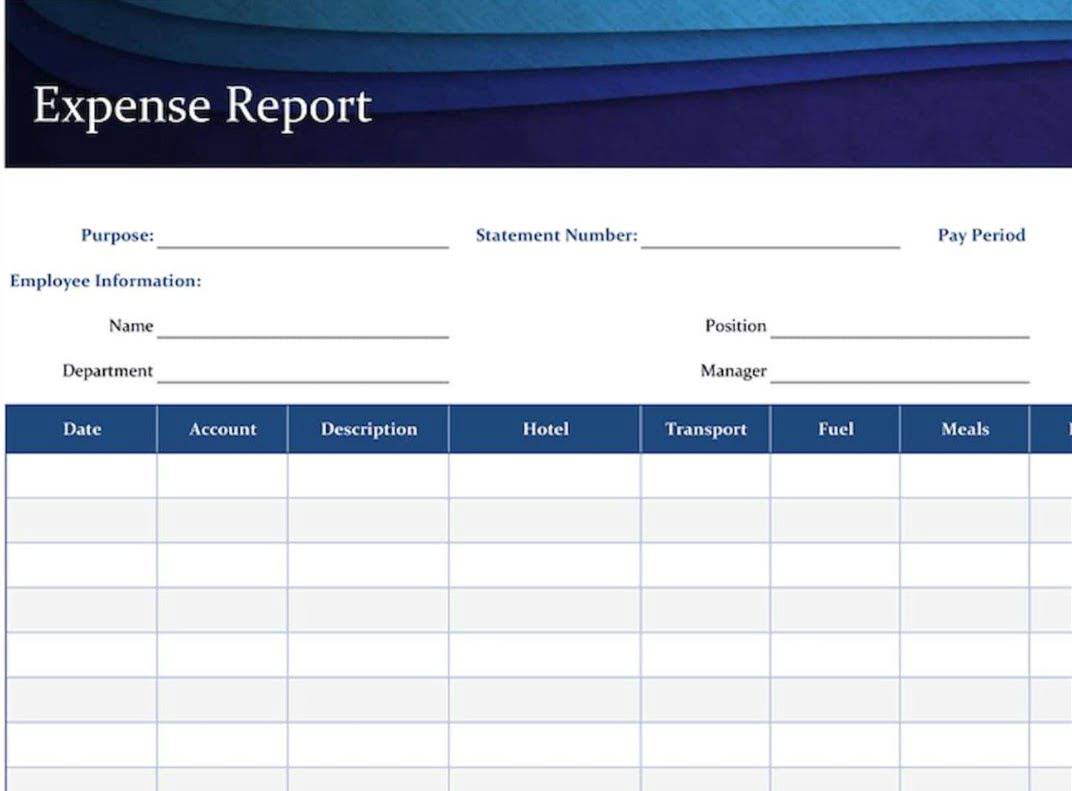

- A company had provided the details of expenses incurred during the year on the production of 1,000 units of product.

- It encompasses both fixed costs (e.g. rent) and variable costs (e.g. materials).

- It means receiving or producing goods only when demanded to minimize inventory holding costs.

- We calculate marginal costs by computing the change in production costs divided by the change in the number of goods produced.

- Knowing the cost of production will let you make a well-informed decision about the markup value.

Reduced Supply Chain Expenses

Another effective strategy involves investing in automation technology. That could how to find total cost per unit include automated warehouses and order fulfillment systems. By maximizing warehouse space efficiency through methods such as adding shelves, organizers, and wall storage, you can optimize storage capacity. But what if their competitor can produce a similar pair of ice skates for only $15.

Understanding Flipkart Video Management System (VMS) for Sellers

His innovative solutions at Upper Route Planner have simplified logistics for businesses across the board. A thought leader in the field, Rakesh’s insights are shaping the future of modern-day https://www.bookstime.com/ logistics, making him your go-to expert for all things route optimization. Leverage Upper’s advanced routing algorithms to create the most efficient routes and save big on delivery costs.

Innovative Technological Solutions

- This includes focusing on reducing expenses related to transportation, warehousing, and inventory management.

- This analysis is essential in identifying where cost savings can occur and monitoring the impact of efficiency improvements in business operations.

- Variable costs include any expenses that increase or decrease in proportion to how many units you are producing.

- It sums up fixed costs, which remain constant throughout the production, and variable costs which fluctuate according to the number of products produced.

- Overhead costs such as rent, utilities, and salaries can all be reduced by implementing efficient business management processes and proactive cost-cutting measures.

- Removing unprofitable products can save on storage fees and free up capital for more productive use within your business.

- Total fixed costs remain the same, no matter how many units are produced in a time period.

ShipBob also helps your online business with tracking distribution metrics and https://x.com/BooksTimeInc inventory management KPIs so you can easily make cost-conscious supply chain decisions. Any expense incurred in the storage of unsold inventory is referred to as holding costs. These costs can range from warehousing to labor costs, to depreciation and opportunity costs. Calculating cost per unit is also important, because it gives ecommerce companies an idea of how much they should charge for each of their products to be profitable.

How to calculate the average fixed cost?

You can also switch to energy-efficient appliances and optimized lighting to optimize utility costs. Cross-training your workers to handle varied tasks can also reduce the dependence on a niche-skilled workforce, cutting labor costs. To begin with, you can outsource non-core tasks to specialized service providers instead of handling everything in-house. It can help cut down labor costs, space requirements, warehousing expenses, and the need for special equipment.

As production increases, your facility rent, machinery depreciation, and labor costs are spread over a large number of units produced, lowering the fixed cost per unit. Bulk production also enables the use of specialized equipment and machinery designed for high-volume business operations, further reducing total production costs. Average fixed cost is the fixed costs to produce one unit of the product. Typical fixed costs are the salary of permanent employees, rent, mortgage payments, etc. We calculate average fixed costs by dividing the total fixed costs by the output level. In this section, we find out how to calculate the average fixed costs.

How to calculate the total cost?

In any business, it’s essential to grasp and track key financial metrics that influence profitability. Let us understand the importance of using a cost per unit calculator through the points below. You can add new rows in the Fixed Cost and Variable Cost table to insert new costs without changing the formula. Get ShipBob WMS to reduce mis-picks, save time, and improve productivity. Quantity sold methods are the techniques a business uses to analyze, forecast, or manage the quantity of goods sold.